Excessive-quality, defect-free, and completely dimensioned metallic elements. Quantum computing energy seems to be set to optimize manufacturing processes within the metalworking {industry}.

A crew led by Professor of Enterprise Informatics Wolfgang Maaß of Saarland College and the German Analysis Heart for Synthetic Intelligence (DFKI) is working with business and educational companions within the “Qasim’ challenge to develop novel quantum-based simulations that merely couldn’t be carried out on in the present day’s standard computing architectures attributable to computing time and storage limits. The crew will probably be demonstrating how these simulations can be utilized to spice up high quality, productiveness, and cost-efficiency at this 12 months’s Hannover Messe.

Aero engines should ship excessive ranges of thrust even beneath adversarial circumstances reliably, so precision is of paramount concern within the manufacture of contemporary plane generators. In turbofan engines, the fan that pulls air into the turbine has a number of blades with advanced curved geometries.

These metallic blades are made by a precision milling course of that requires a cautious machining technique. Precision milling is barely attainable if the relative movement of the device and the workpiece may be very tightly managed. Failure to take action can imply that the blade begins to vibrate, inflicting the floor of the blade to hit the milling head in an uncontrolled method and damaging the blade.

For a element that turns into basically unusable, even when very barely out-of-spec, this could be a very costly mishap. “This sort of manufacturing error might be extraordinarily pricey for producers of high-precision aero engine elements,” mentioned Wolfgang Maaß, professor of enterprise informatics at Saarland College and head of the Sensible Service Engineering analysis space on the German Analysis Heart for Synthetic Intelligence (DFKI).

However the state of affairs is comparable for a lot of different corporations, giant and small, that manufacture metallic elements—together with these produced by laser slicing. The intense warmth that’s generated in the course of the slicing course of could cause the metallic to increase in locations the place it shouldn’t. In standard slicing operations, off-cuts can get caught within the machine, which then involves a halt.

The result’s elevated rejection charges and prolonged machine downtimes, costing the manufacturing firm materials, money and time. “The metalworking {industry} is a significant financial sector in Germany and the EU, and security and high quality requirements are excessive. Manufacturing processes within the metalworking sector typically have rejection charges of about 1%, which does not sound like a lot, however total, it could have a big affect on competitiveness,” defined Wolfgang Maaß.

A discount in rejection charge might be achieved by digital simulations that make use of synthetic intelligence. By making a digital twin of the workpiece, the whole lot that occurs to an actual element might be simulated in a digital atmosphere—from planning and manufacturing to high quality assurance.

In principle, each side of the manufacturing chain might be exactly optimized, whether or not it’s the good spindle pace for milling or the best energy density delivered by the laser. However there is a catch. The large quantity of information required to supply these high-resolution simulations merely can’t be dealt with with standard laptop methods. Quantum computer systems, which might ship the extent of computing energy wanted, will not be but obtainable.

The outcome? “Simulations are at present not often utilized in sensible purposes. Partly, as a result of adequate computing energy is simply not obtainable, and partly as a result of specialised knowledge and knowledge are wanted, which in flip requires detailed experience in computational simulations,” defined Hannah Stein from Maaß’ analysis crew. At current, metalworking corporations should content material themselves with lower-resolution digital twins, and so they rely closely on the sensible experience and expertise of their manufacturing engineers.

And there may be nonetheless some technique to go earlier than quantum computer systems ship the form of warp-speed computing wanted to deal with large knowledge volumes. The analysis companions within the Qasim challenge are, nonetheless, firmly rooted in actuality. The consortium of business and educational companions is engaged on short-and long-term options that harness the facility of quantum methods to ship enhanced simulations to be used in manufacturing situations.

“Our preliminary research have proven that by exploiting the ideas underlying quantum mechanical methods and utilizing quantum-based machine studying methods, we will remedy algorithmic issues considerably quicker,” mentioned challenge coordinator Wolfgang Maaß.

“Though in the present day’s quantum computer systems are nonetheless of their infancy, the underlying know-how can already be deployed in areas the place standard computer systems can be working at their limits, requiring immense quantities of time to finish a calculation.”

The researchers are utilizing quite a lot of quantum computing strategies to discover methods of creating advanced simulations quicker and appropriate for sensible purposes. The work entails making use of quantum computing applied sciences to standard simulation strategies primarily based on mathematical fashions from physics and supplies science. The analysis crew can also be investigating quantum-based machine studying strategies.

By evaluating these new approaches with standard methodologies and assessing the efficacy of the assorted options, the crew is creating modern options that might discover sensible purposes within the close to future. The outcomes are already being built-in into current simulation strategies.

“We’re at present creating the primary prototypes. Up to now, probably the most promising outcomes have been achieved utilizing hybrid fashions that mix standard simulation methodologies with quantum know-how and machine studying,” mentioned doctoral researcher Hannah Stein.

Because the researchers use manufacturing knowledge from actual manufacturing traces, aero engine producers could quickly be utilizing quantum computer-based simulations to foretell blade vibrations throughout milling.

By working with an correct digital twin, they will exactly set machining parameters, similar to milling pace, enabling them to eradicate machining inaccuracies and considerably scale back rejection charges. Improved simulations additionally imply that laser cutters can ship the correct quantity of energy throughout an optimized machining sequence, producing undamaged, completely dimensioned metallic elements.

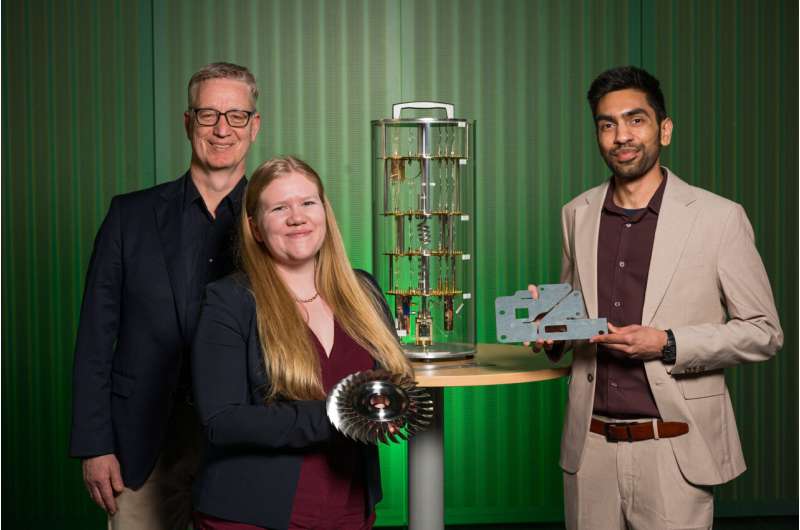

At this 12 months’s Hannover Messe, the enterprise informatics specialists from Saarbrücken will probably be showcasing milling and laser slicing prototypes that display how standard manufacturing might be enhanced by quantum-based simulations by delivering shorter materials processing instances and improved product high quality.

Saarland College

Quotation:

Harnessing quantum know-how for {industry}: Chopping-edge simulations for Trade 4.0 (2024, April 11)

retrieved 14 April 2024

from https://techxplore.com/information/2024-04-harnessing-quantum-technology-industry-edge.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.