EDITED: wants clarification if temps listed are F or C

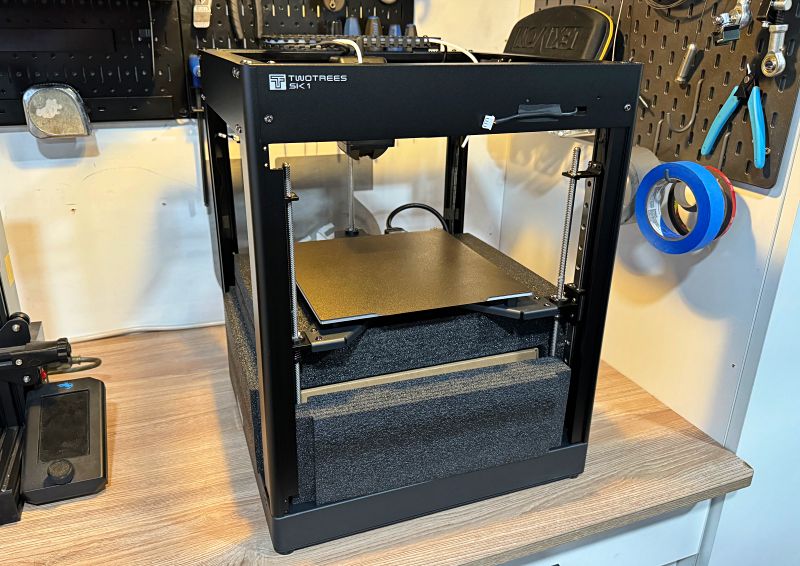

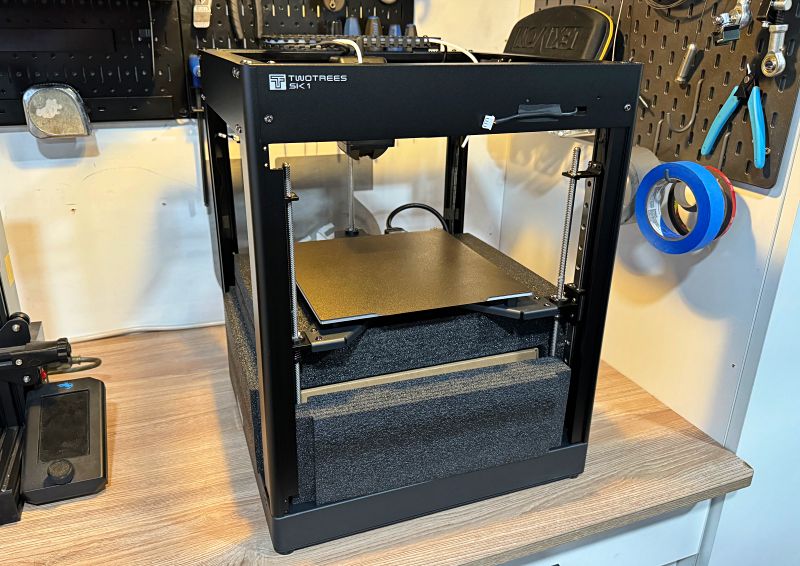

REVIEW – 3D printers simply preserve getting higher and higher. The most effective machine remains to be prone to be one you have already got and know the best way to use, however in case you’re on the lookout for new options or quicker speeds, or are simply on the point of drop money in your first printer, there’s by no means been a greater time. Living proof: TwoTrees has simply launched the SK1 CoreXY printer, and it’s been my greatest expertise but.

What’s it?

The TwoTrees SK1 CoreXY is a 3D printer that makes use of the CoreXY movement construction (extra on that later). It’s blazing quick at as much as 700mm/s, helps WiFi printing, has a big print space of 256mm³ and helps a number of supplies.

What’s within the field?

- TwoTrees SK1 CoreXY 3D Printer

- Energy twine

- Contact display and mount bracket

- WiFi antenna

- Meeting handbook

- Instruments

- Starter roll of filament

- USB-A TF and adapter

{Hardware} specs

Velocity: As much as 700mm/s | 20,000 mm/s² | Stream 32mm³/s

Sizing: Print = 256 x 256 x 256mm | Machine = 400 x 400 x 530mm

Display screen: 4.3″ Coloration capacitive contact display

Leveling: Z-Tilt + 36 factors mattress mesh

Firmware: Klipper (open supply) that includes enter shaping, movement advance and extra

Nozzle: 0.4mm diameter, filament diameter or 1.75mm, heats as much as 300º in 30 seconds

Filament Varieties: PLA | PETG | ABS | ASA | TPU | PC | UltraPA

Extruder: Twin-gear direct extruder

Print: USB, LAN, WiFi | Format = G-Code

Print Mattress: Magnetic PEI Plate

Accuracy: Print = ±0.1mm | X/Y/Z axes = ±0.0025mm

OS Assist: MacOS | Home windows | Linux

Design and options

The TwoTrees SK1 CoreXY is a 3D printer that makes use of the CoreXY movement construction. That implies that the extruder strikes on each the X and Y axes. The print mattress makes use of three drive shafts (entrance left, entrance proper and heart rear), permitting it to tilt for automated leveling. A capacitive contact panel permits simple management and upkeep, whereas a WiFi or LAN connection permits distant internet monitoring and intensive reporting.

The print mattress is heated (as much as 100º) utilizing a magnetic plate however with the small element of including rear anchors to ensure alignment. It simply makes issues simpler, and the feel creates a clear visible on no matter floor you may have going through down.

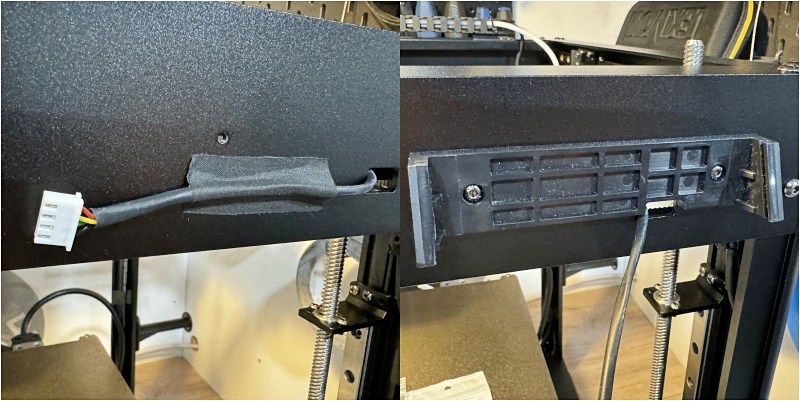

Energy and filament to the extruder are already routed by a tank/tread/chain construction protecting all the things clear.

A built-in LED contained in the entrance panel illuminates your in-process prints properly.

Setup

The TwoTrees SK1 CoreXY 3D Printer arrives nearly totally constructed. The meeting course of entails eradicating a couple of screwed-in delivery blocks, assembling the display and securing the drive shafts. There’s a QR code to scan for up to date documentation, however let’s stroll by it. Begin by eradicating the froth items that saved all the things secure throughout delivery.

Subsequent take away these screwed in blocks that saved all the things locked down. Set up the equipped screws the place the blocks have been. I consider there have been 8 and there have been a pair that weren’t current on my machine.

Set up the filament spool hanger on the proper facet.

Put together for the display by releasing the cable and putting in the mounting bracket.

Join the cable to the port on the again of the display, after which slide the display down onto the bracket.

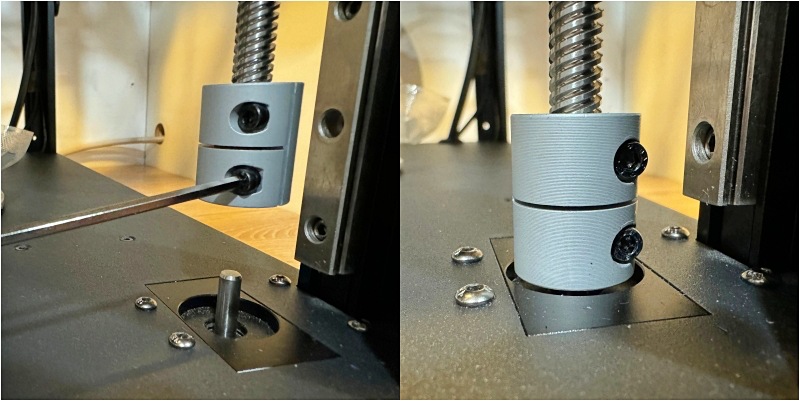

This step had the least steerage. I manually spun every of the three drive shafts till totally lowered to flush with the primary floor, however above the recessed ground to forestall direct contact. Then tighten the decrease screw with the included hex wrench. Examine the higher screw whilst you’re at it.

Set up the WiFi antenna onto the put up and we’re about able to go. On the other facet, ensure that the recessed change is ready to the proper voltage to your nation.

Join the ability twine and flip the crimson change to energy up the SK1. Give it a minute to begin up after which navigate to the settings display to arrange a connection to your WiFi. Be aware the IP deal with if you see it on the display as you’ll want that for distant entry whether or not on WiFi or LAN.

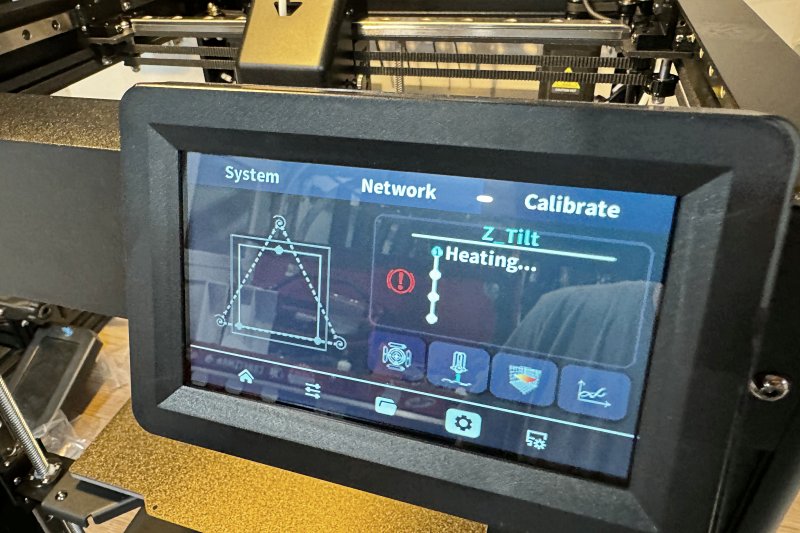

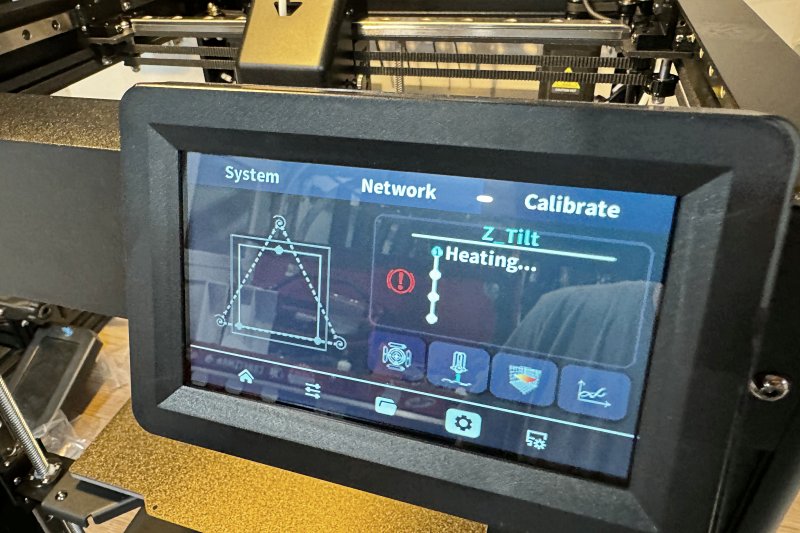

The final step is to calibrate all the things. Under is that display. So as from left to proper, you’ll press the icon for every of the next…

Z-Tilt calibration, Probe calibration, Mattress Mesh calibration, and Vibration calibration.

All of those are totally automated and can end on their very own except for the Probe calibration. After the heating, it’ll take 3 probe measurements after which wait so that you can calibrate ultimate distance utilizing a sheet of paper and the Z up/down controls. That is fairly simple, however remember the fact that the down arrow means shifting the probe nearer to the mattress. That will appear apparent, however as a result of the mattress strikes as much as make that occur it’s simple to get confused. Additionally the actions are in 0.2, 0.1 and 0.02mm increments, that are small, and the mattress strikes away after which nearer with every adjustment, so it may possibly generally really feel prefer it isn’t getting nearer. Simply begin with 0.2 and go slowly, switching to finer actions as you get shut. Cease if you really feel a small quantity of drag on the paper as you pull.

Set up the filament reel onto the hanger and start to feed filament into the tube till it stops. The in-built lights ought to flash twice at this level. On the display, navigate to Controls (one to the proper of the house icon) after which select load/unload, and press the load button. The extruder ought to start to tug the filament. If not, chances are you’ll have to push the filament manually and/or examine for any onerous angles within the tubing which might be stopping the filament from sliding easily. The extruder will take over and run about 15 seconds of filament after which you’re prepared.

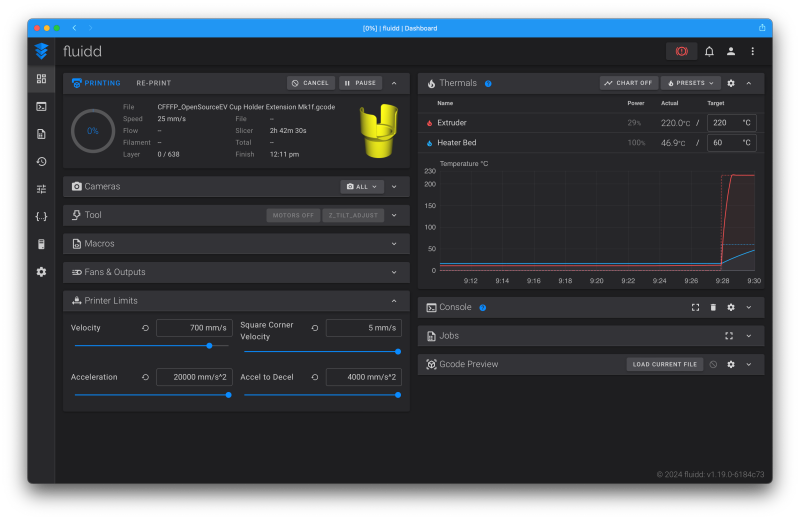

The final step is to open a browser in your laptop and sort within the IP deal with famous earlier. Once you hit return, you’ll be introduced with their internet interface known as Fluidd. Right here you may monitor and management nearly each side of a print undertaking.

Efficiency

My expertise with shopper 3D printers has been restricted to 2 fashions by Creality. The Ender 7 (additionally a CoreXY), which I reviewed two years in the past, and the Ender 3 Professional, which I purchased for myself after letting my son run off with the Ender 7. I acquired fairly comfy with the three Professional however was on the lookout for extra options.

The TwoTrees SK1 CoreXY 3D Printer is an ideal improve for me. It has a print mattress that’s a further 20mm in each the X and Y axes, however for me the most important enhancements have been the velocity and distant skills. With the ability to use my slicer of alternative (Cura), after which ship on to the printer with a begin print command, is superior. Be aware that this does require the printer to be on.

Each the mattress and the extruder warmth shortly and maintain temperatures precisely. The trickiest half (as typical) is discovering one of the best temps and settings for every materials you’re going to make use of. Discover a good temperature tower to print and get within the behavior of printing one for every new materials. It’s additionally been colder than typical right here and since my printer is within the storage, I’ve needed to make a couple of changes for that as properly.

I bumped into only a few points. I needed to barely tighten the belt pressure as I had a pair slips within the first benchy construct. The show appears to lock up often on longer builds and is barely corrected by a restart. I’m hoping there might be a display firmware replace to repair that quickly. It’s solely been launched not too long ago, so I might count on to see some updates over the following couple of months. I additionally observed that each one the edges have a recessed space with tapped screw holes to just accept plexi panels. I don’t know if that’s within the works or not, however I’ll in all probability laser reduce some myself to assist temperature and humidity management in my storage.

So far as supplies go, I often follow a PLA or PETG. TwoTrees despatched alongside their high-speed PLA that was remarkably constant. Right here’s a excessive decision print of the moon that I examined with. The element was spectacular.

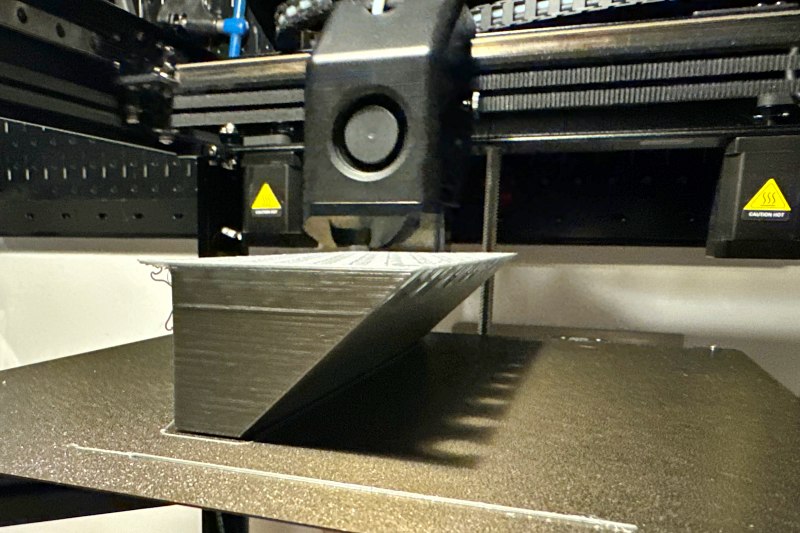

The heated mattress additionally did a very good job of supporting some prints with giant overhangs with out help construction, like this earlier try at a Hex Wrench holder I designed within the Shapr3D app for iPad.

Right here’s the revised print to make use of much less materials and angle the wrenches out.

I additionally printed some filament bearing rollers appropriate with the IKEA skadis grid. They got here out like this.

Right here’s a video of these in course of the place you may see the velocity, accuracy and get an thought of the machine’s sound.

And at last a Benchy to your reference. Very clear and really quick.

What I like

- Tremendous quick and constant prints

- Bigger print sizes of 256mm³

- WiFi printing and administration

- Constructed-in lights

What I’d change

- Higher meeting and use directions

- Touchscreen often turns into unresponsive requiring a restart

- WiFi often drops out the place distant management panel can not join

Ultimate ideas

At a full retail value of $599, the TwoTrees SK1 CoreXY 3D Printer is simple to arrange, and it’ll have you ever printing efficiently very quickly. Whereas the directions is usually a bit obscure, they’re sufficient to get you began, and the online interface supplies extra management than most customers will want. Discover your favourite slicer and get after it.

Value: $599 – At the moment at $499 unbundled with US Plug

The place to purchase: TwoTrees

Supply: The pattern of this product was offered by TwoTrees.

![The Most Visited Websites in the World [Infographic]](https://newselfnewlife.com/wp-content/uploads/2025/05/Z3M6Ly9kaXZlc2l0ZS1zdG9yYWdlL2RpdmVpbWFnZS9tb3N0X3Zpc2l0ZWRfd2Vic2l0ZXMyLnBuZw.webp-120x86.webp)