Hyperspectral cameras cut up the sunshine mirrored by an object into many slim spectral bands, which they seize and course of individually. That method, they file a spectral signature for every pixel in a scene. This signature is way richer than the red-green-blue picture that our eyes seize. It could even uniquely establish the fabric within the image since every molecule interacts with mild in a particular method, leading to a spectral fingerprint. These distinctive fingerprints are of fantastic worth for figuring out and classifying all types of supplies and objects, and they’re important for additional automation in industrial processes. It permits us to, e.g., reveal the corrosion on the structural components of a bridge.

The commonest implementation of those cameras is named a “push-broom,” which scans a scene line by line and takes a number of seconds and even minutes. Moreover, these cameras are assembled by hand from many discrete elements, together with costly and heavy precision optics within the glass. It requires cautious alignment and calibration. These implementation components imply solely consultants in hyperspectral imaging can calibrate, right, and interpret the hyperspectral information into precise business options.

Push-brooms do an incredible job in a conveyor-belt state of affairs however have difficulties with a digital camera or scene in free motion. Consider an inspection digital camera in a probe robotic or a free-flying drone. For these, you want to scan entire frames, ideally at video pace, to look at real-time modifications. For instance, when a robotic takes random gadgets out of a bin, it should take photos completely to make new choices after every motion. When the picture will get refreshed at a charge of, e.g., 30 frames per second, this ends in a hyperspectral video. Right now, hyperspectral video is able to use in all kinds of business contexts: high quality inspection, sorting, and materials detection. So how did we get there? The quick reply: is chip know-how.

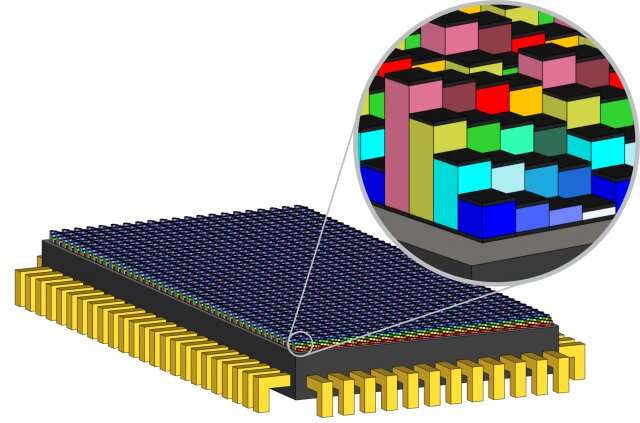

Utilizing CMOS-based infrastructure and course of know-how in a cleanroom, imec developed a chip with built-in hyperspectral performance by constructing interference-based optical filters on the wafer degree, depositing and patterning them instantly on high of picture sensor pixels. This method introduced essential aggressive benefits: the built-in imagers could be mass-produced at a price akin to commodity laptop chips. Moreover, they’re small in order that they are often inserted into an everyday digital camera with normal lenses. Such a digital camera is appropriate for mounting a drone or a small robotic.

The hyperspectral chip combines the accuracy of conventional scanning know-how with elevated comfort, delivering fast refresh charges of the scene. It could scan as much as 2,880 traces per second, overlaying the sector of view with 2048×1088 pixels at a pace of about 30fps in daylight situations and as much as 340fps at larger illumination ranges, as usually utilized in machine imaginative and prescient functions. The power to manufacture extraordinarily compact, dependable, and cost-efficient hyperspectral performance on a chip is essential to bringing any such imaging into new markets.

Mosaic patterning know-how

Mosaic patterning know-how is used to realize video mode hyperspectral imaging. The pixels are grouped into 3×3, 4×4, or 5×5 arrays. On high of every such group of, e.g., 16 pixels within the 4×4 mosaic sample, 16 narrow-band filters are processed, successfully making filters the scale of 1 imager pixel. With this mosaic design, there isn’t a longer a necessity for separate duplicator or beam-splitting {hardware}.

For industrial functions, a scientific degree of knowledge quantity is just not essential. Getting the correct spectral bands required for the applying is essential. The appliance specs could be met by choosing the correct picture sensor with the precise pace, sensitivity or variety of pixels.

Enhancements throughout the whole ecosystem

Along with chip integration, collaboration throughout the whole worth chain was wanted to assist shut the hole between a promising know-how and its utility within the business: from digital camera {hardware} producers to end-users. In that context, researchers of imec partnered with Photonfocus to construct light-weight and compact cameras across the built-in chips. As well as, the imec researchers validate the spectral efficiency of each digital camera, and the end-users obtain direct help and software program entry. The outcome? Unprecedented system efficiency whereas considerably lowering the adoption barrier.

Talking of {hardware}: we have to have a look at mild. A superb multispectral picture begins with the right lighting. After completely analyzing completely different mild sources, e.g., LED, halogen, and light-weight bulb, imec researchers began co-innovating with Effilux. Steady suggestions on the spectral vary, energy, and stability, yielded the right match with the built-in sensors.

On the different finish of the worth chain, the primary problem for the end-user was to have the ability to interpret hyperspectral information, with no need to be an professional in machine studying or hyperspectral imaging. Two software program corporations, perClass, and Luxflux, have constructed a software program suite for it, elaborating on imec’s APIs, software program, and the algorithms for information processing behind it, decreasing the doorway barrier for hyperspectral insights.

Shortcut from downside to hyperspectral imaging answer

These enhancements throughout the worth chain have virtually lower out the R&D part for shoppers within the business, closing the hole between an issue and its hyperspectral imaging answer.

Bringing collectively information from end-users to {hardware} proved important to creating the market mature. New hyperspectral functions and adjoining software program corporations are rising in precision farming, ecosystem safety, corrosion detection and remedy, mining, meals inspection, and gasoline leak detection, amongst others. A promising know-how has been put to work.

Imec introduces broad spectrum hyperspectral imaging options

See www.imechyperspectral.com/en

Quotation:

Hyperspectral imaging on an built-in chip (2022, October 24)

retrieved 24 October 2022

from https://techxplore.com/information/2022-10-hyperspectral-imaging-chip.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.