Capturing clear objects in three dimensions is a serious problem. Researchers at Fraunhofer Institute for Utilized Optics and Precision Engineering IOF have developed a sensor that is ready to resolve this downside. The system has now been efficiently examined for the primary time with a robotic. Purposes in large-scale industrial manufacturing processes such because the semiconductor or automotive trade may very well be potential. The sensor shall be featured on the Hannover Messe Preview on March 16 and on the German commerce festivals Management from Might 3–6, in addition to Hannover Messe from Might 30–June 2, 2022.

Clear objects have their drawbacks: It’s not with out purpose that now we have stickers of birds’ silhouettes on large glass home windows so as to shield their real-life conspecifics from colliding with the clear barrier. Simply as these animals have difficulties recognizing clear surfaces, robots are additionally restricted of their capabilities: They can not “see” glass or different so-called “uncooperative surfaces,” i.e., surfaces which can be shiny metallic, extraordinarily reflective, or jet-black. Particularly in an industrial atmosphere, this has been impeding the usage of robots up to now. Many tasks of automatization stagnate as a result of uncooperative surfaces might solely be detected too slowly or too inaccurately in 3D measurement.

Thermographic 3D sensor makes clear objects seen to robots for the primary time

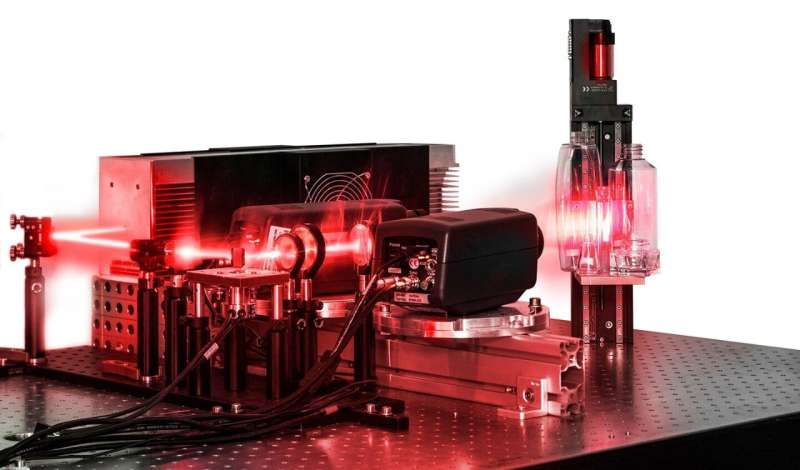

A brand new 3D measurement method, developed by researchers at Fraunhofer IOF final yr, solves this downside: The “MWIR 3D Sensor”—additionally referred to as “Glass360Dgree”—can detect objects with reflective or light-absorbing surfaces spatially and reliably for the primary time. For this objective, the system combines infrared laser projection and thermography: After domestically heating up the article to be measured, two thermal imaging cameras decide the ensuing temperature distribution on the article’s floor. Opposite to conventionally used sensors, the newly developed system doesn’t require further measurement aids or particular, quickly utilized markings, for instance within the type of (spray) paint.

Excessive measurement velocity for purposes in large-scale industrial processes

Manufacturing processes are sometimes about velocity mixed with top quality. This implies: The extra work steps a system can carry out per minute with out producing faulty merchandise, the extra worthwhile is the manufacturing. The researchers at Fraunhofer IOF have taken this self-image of trade as a chance to adapt “Glass360Dgree” to numerous manufacturing eventualities. In latest months, the researchers from Jena have succeeded in growing the measurement velocity accordingly and optimizing the parameters of the measurement area.

“Our analysis group has been cooperating for years with firms from a variety of manufacturing fields,” explains Dr. Stefan Heist, head of the “3D Sensors” analysis group at Fraunhofer IOF. “Amongst them are firms from semiconductor manufacturing, the automotive trade and aviation. We checked out joint tasks from the previous and analyzed how our 3D glass sensor might obtain higher outcomes than typical sensors in numerous software eventualities,” explains the researcher, who has been working vigorously on new strategies for 3D measurement for years. “We had been in a position to determine three key beginning factors to make our system prepared for potential use in a large-scale industrial manufacturing facility.”

The staff discovered the best steadiness between the extent of element wanted in decision and the length of a measurement. In addition they investigated numerous choices for the optical setup of their 3D sensor so as to variably adapt the measurement area to the duty at hand and the house out there inside a producing plant. As well as, the staff led by Dr. Stefan Heist and Martin Landmann, additionally researcher at Fraunhofer IOF, labored carefully with researchers from the Ilmenau College of Know-how to optimize the information processing of their measurement system. The staff from Ilmenau succeeded in effectively deriving the lively management of a robotic and its respective instruments from the obtained measurement knowledge.

A brand new dimension in flexibility and variety

With its nice flexibility and unprecedented versatility within the properties of the objects to be scanned, “Glass360Dgree” opens up utterly new potentialities within the automation of commercial processes in addition to in product design.

The thermographic 3D sensor makes use of thermal radiation and imaging for 3D detection. A high-energy CO2 laser and a cell optical setup with particular lenses challenge a line shifting in a number of steps over the measured object in fractions of a second. All through the measurement, the article absorbs the vitality of the laser mild and emits it clearly seen to the 2 extremely delicate thermal imaging cameras.

Particular software program developed at Fraunhofer IOF analyzes the photographs of the warmth signature left by the slim infrared line on the article for a short while. The software program makes use of the 2 differing viewing angles and the ensuing deformation within the recorded fringe sample to reconstruct the spatial coordinates. It then merges the information into the precise dimensions of the measured object. The thermal vitality launched for the 3D evaluation is so low that the article isn’t broken: The temperature distinction between heated and non-heated surfaces is usually lower than 3 °C.

Glass360Dgree shall be introduced by Fraunhofer IOF to a specialist viewers inquisitive about automation and metrology on the German Hannover Messe on the Fraunhofer joint sales space in Corridor 5, Stand A06 from Might 30 to June 2, 2022, and at Management, the worldwide commerce honest for high quality assurance, from Might 3 to six, 2022.

Compact system designed for high-precision, robot-based floor measurements

Fraunhofer-Gesellschaft

Quotation:

Sensor for capturing clear objects in three dimensions (2022, March 16)

retrieved 21 March 2022

from https://techxplore.com/information/2022-03-sensor-capturing-transparent-dimensions.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.