REVIEW – EM-Sensible has not too long ago introduced their latest laser engraver, the EM-Sensible Twin Desktop Laser Engraver. I’m at all times excited by reviewing lasers, however rather more than that, I’m at all times excited by reviewing objects from a producer that’s new to me.

⬇︎ Soar to abstract (execs/cons)

Worth: $3499.00

The place to purchase: EM-Sensible

What’s it?

The EM-Sensible Twin is an enclosed desktop laser engraver that options each a 20W fiber laser supply and a 20W diode laser supply.

What’s included?

- Em-Sensible Twin

- Energy Adapter

- USB-B Cable

- USB-C Cable

- Fast Begin Information

- Person Guide

- Exhaust Hose

- USB-Drive

- Hex Wrench

- Pattern Materials Package

- Alignment “L” bracket

- Security Glasses

Tech specs

Laser: 20W fiber, 20W diode

Work Space: 230mm x 230mm, max top, 150mm

Max Pace: 10,000 mm/s

Enclosure: Sure

Digicam: 4k

Software program: Lightburn & EZCAD

Rotary: Optionally available

Design and options

The EM-Sensible Twin arrived properly packaged in thick foam safety. The machine is a horny and modern design that may match on nearly any desktop. There is no such thing as a meeting to carry out, simply join the exhaust hose, take away the lens cowl, plug within the energy and USB cables and also you’re able to go.

The left facet of the machine has a guide focus knob and the appropriate facet of the machine has up/down focus buttons, an influence button, and an emergency cease change.

I adopted the quick-start information to attach the EM-Sensible Twin to the Lightburn software program. I did have some issues at first because of the launched software program from Lightburn being an older model, however after messaging EM-Sensible, I used to be capable of get it working with the model they included on the USB flash drive and a few slight changes to the settings.

The EM-Sensible Twin has a laser protected enclosure that raises and lowers on a spring loaded rail. The enclosure opens 10.4″ (265mm) for simple entry to the working space. The bottom plate options M4 threaded holes spaced at 25mm for securing objects with jigs (fixtures) or the included “L” bracket. The bottom plate can also be twin use, it has a chopping floor (raised venting) on one facet for chopping, and flat on the opposite.

I just like the detachable base plate. My different fiber laser doesn’t have this characteristic. The detachable base plate makes it a lot simpler to create fixtures that self-locate within the gap for the bottom plate. Having the ability to take away the bottom plate additionally means you’ll be able to place objects beneath the EM-Sensible Twin for engraving. The closest I can inform, it may well focus as much as 1″ (25mm) under the machine (desk floor). The twin-use base plate was a welcome characteristic.

One of many causes I selected this evaluate was for the Lightburn software program expertise. I haven’t used Lightburn a lot, just a bit on one in every of my associates’ lasers. I actually wished to match the expertise to different proprietary software program that I’ve used on different lasers. I assumed this is able to be an awesome perception as to how a first-time laser consumer would expertise the machine.

Now it was time to make use of the laser to create one thing. I’ve been used to different lasers which have proprietary software program with built-in presets for numerous supplies. The EM-Sensible Twin makes use of the third occasion software program referred to as Lightburn, so chances are you’ll be by yourself for determining what settings to make use of. The EM-Sensible web site does have settings for a few of their different lasers, however as of this evaluate, none for the EM-Sensible Twin but. There are a couple of articles of their weblog part of the web site for the EM-Sensible Twin. That is maybe the most important hurdle for a first-time laser consumer, it’s going to contain loads of trial and error to determine settings.

After I positioned the metallic enterprise card on the bottom plate to set the main target, I seen instantly that the pink laser focus dots have been a lot simpler to see than one other fiber laser that I’ve. I do want they might implement some type of crosshair focusing system, as it may be laborious to see when the dots are aligned correctly with my unhealthy close-up imaginative and prescient.

I had a tough concept of the settings to make use of as a result of my different fiber laser has the identical energy. I threw in a take a look at card and ran the laser at 4000 mm/s and an influence of 90%. I ran my The-Gadgeteer enterprise card take a look at, and it got here out nice.

In Lightburn, the lasers are merely known as “Laser 1” and “Laser 2.” I wasn’t 100% which was which, so I ran a fast take a look at on wooden and metallic and decided that “Laser 1” is the fiber laser.

Subsequent, I engraved a 30mm sq. to test for scale accuracy and located that it was manner off. The sq. got here out about 35mm. I might have seemed up how to do that on the web, however I made a decision to make use of this as a possibility to check out the EM-Sensible assist by way of my contact, they usually shortly instructed me how I might calibrate it.

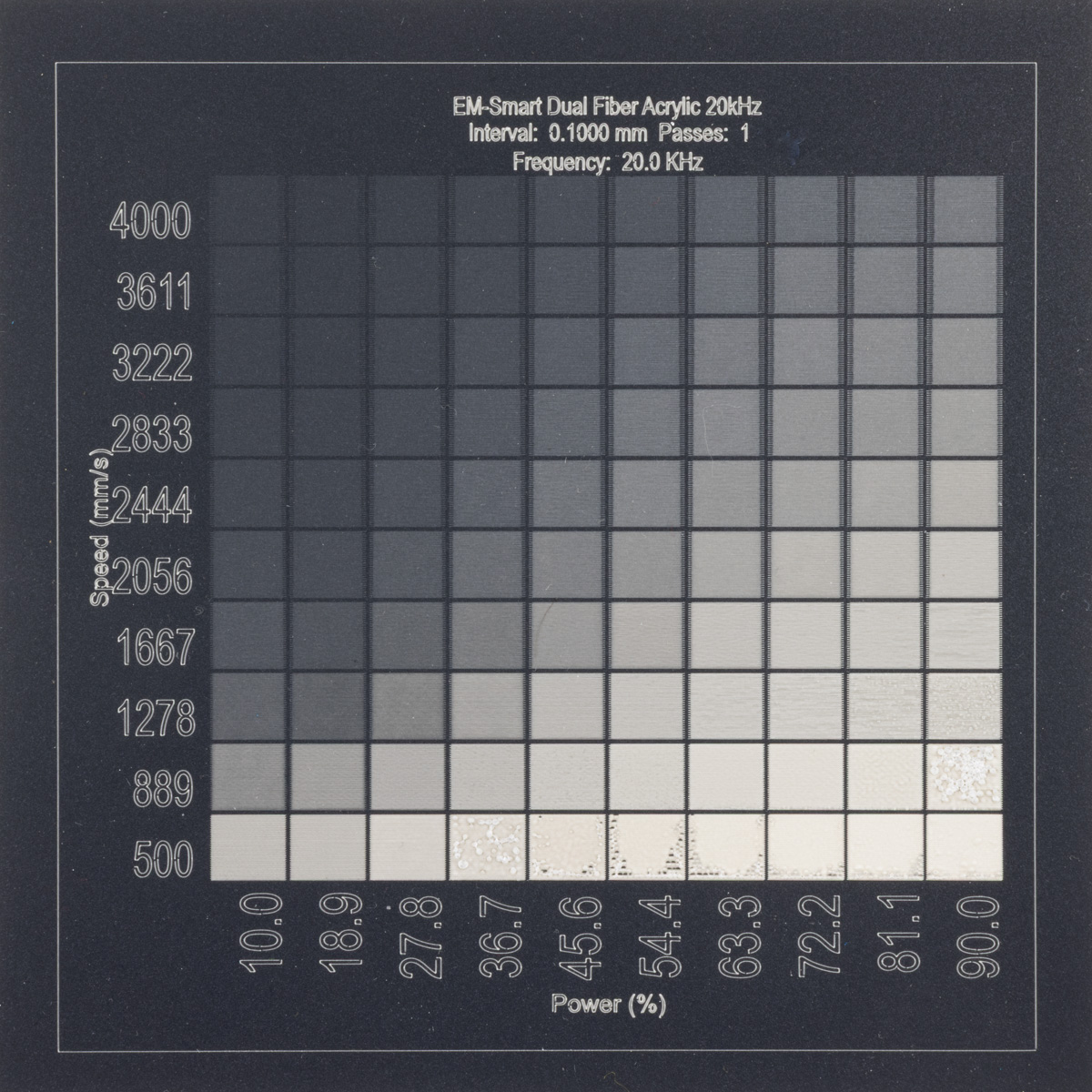

Because the pattern materials pack included some acrylic, I ran a couple of checks to get an concept of the ability and velocity wanted, then I ran a cloth take a look at. I don’t significantly like the best way Lightburn does its materials take a look at, however that’s not likely something that EM-Sensible can management. I desire the best way different software program generates a mission that you could modify, particularly to suit the take a look at within the desired space.

Now that I had a reasonably good concept of what settings to make use of on acrylic/plastic, I used the laser to place my identify on my cordless instrument batteries in order that when individuals borrow them, I can be certain that I get them again. Marking my instruments is one thing I’ve been doing extra of recently, and the velocity and functionality of the fiber laser make it a really fast job.

Transferring on to slate, I ran a take a look at grid utilizing a velocity of 100 to 1000 and energy from 10 to 100%. The EM-Sensible additionally carried out very properly and the framing makes aligning the picture a lot simpler than a grantry type diode or CO2 laser.

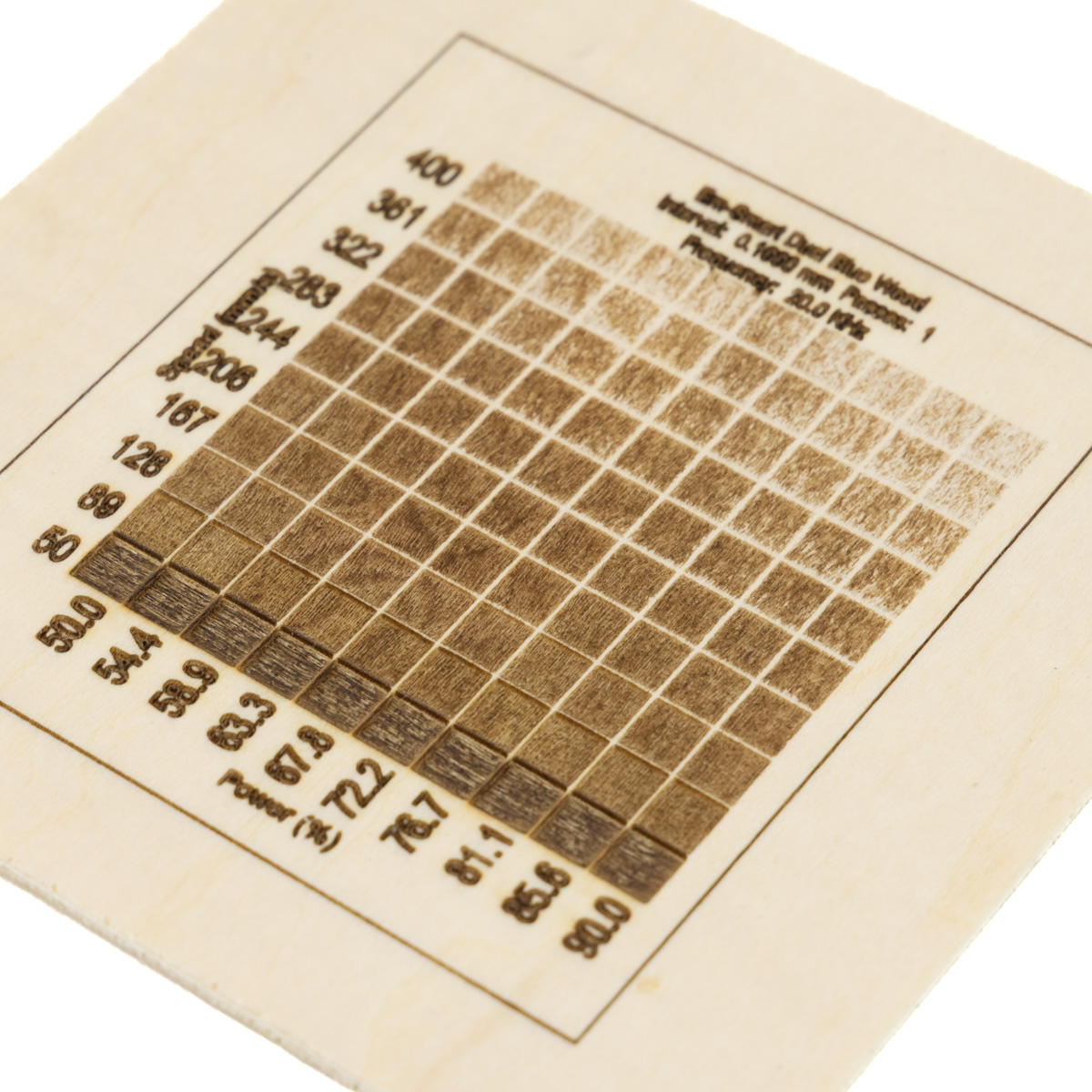

Wooden engraving was subsequent on the record of issues to attempt. I ran a take a look at grid from 400 to 800 mm/s and 50 to 80% energy, which turned out to be a bit quick. Subsequent, I ran a take a look at grid from 50 to 400 mm/s and 50 to 90% energy. This resulted in a wonderful vary of engraving settings to select from. After a few checks of chopping, I created the next engraving.

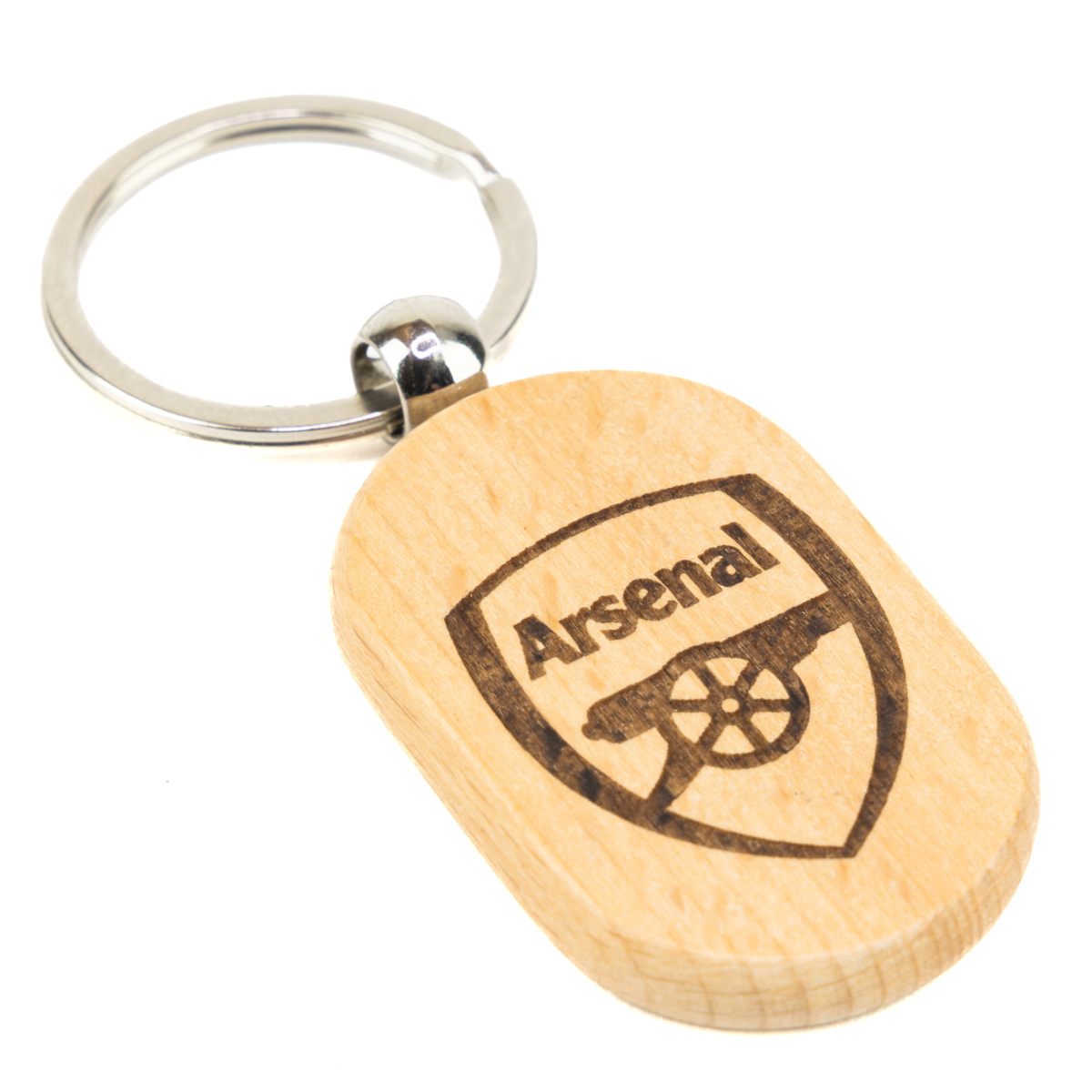

I had a bunch of key rings, so I made a decision to experiment with the settings for these. I wiped out one in every of them earlier than I noticed that I had the road spacing at 0.03 vs 0.1mm. I had used 0.03 for metallic, and didn’t discover that the setting stayed between classes. These have a good quantity of depth, but it surely doesn’t present very properly within the images.

I had a type of inflexible wallets that somebody despatched me, so I made a decision to offer {that a} attempt. I solely had one shot at it, so I principally guessed on the settings based mostly on the black metallic enterprise card settings. I did run a few of it with a number of passes in separate jobs. The alignment was good between jobs (as anticipated).

Subsequent, I selected to attempt a metallic coin. I knew the 20W laser wouldn’t be excellent for depth engraving cash, so I used to be aiming to simply mark on them. I struggled for fairly some time with the settings. I attempted fairly a couple of settings and simply couldn’t get a lot of a mark on the coin. I contacted EM-Sensible, and after suggesting that I attempt a 0.03 mm line spacing, I used to be lastly capable of get a darkish mark on the coin. In case you’re trying to do metallic cash, I might contemplate getting a higher-powered laser, because the 20W fiber laser takes a very very long time to make a coin, particularly if you happen to’re on the lookout for important engraving depth. These cash took about an hour and a half every.

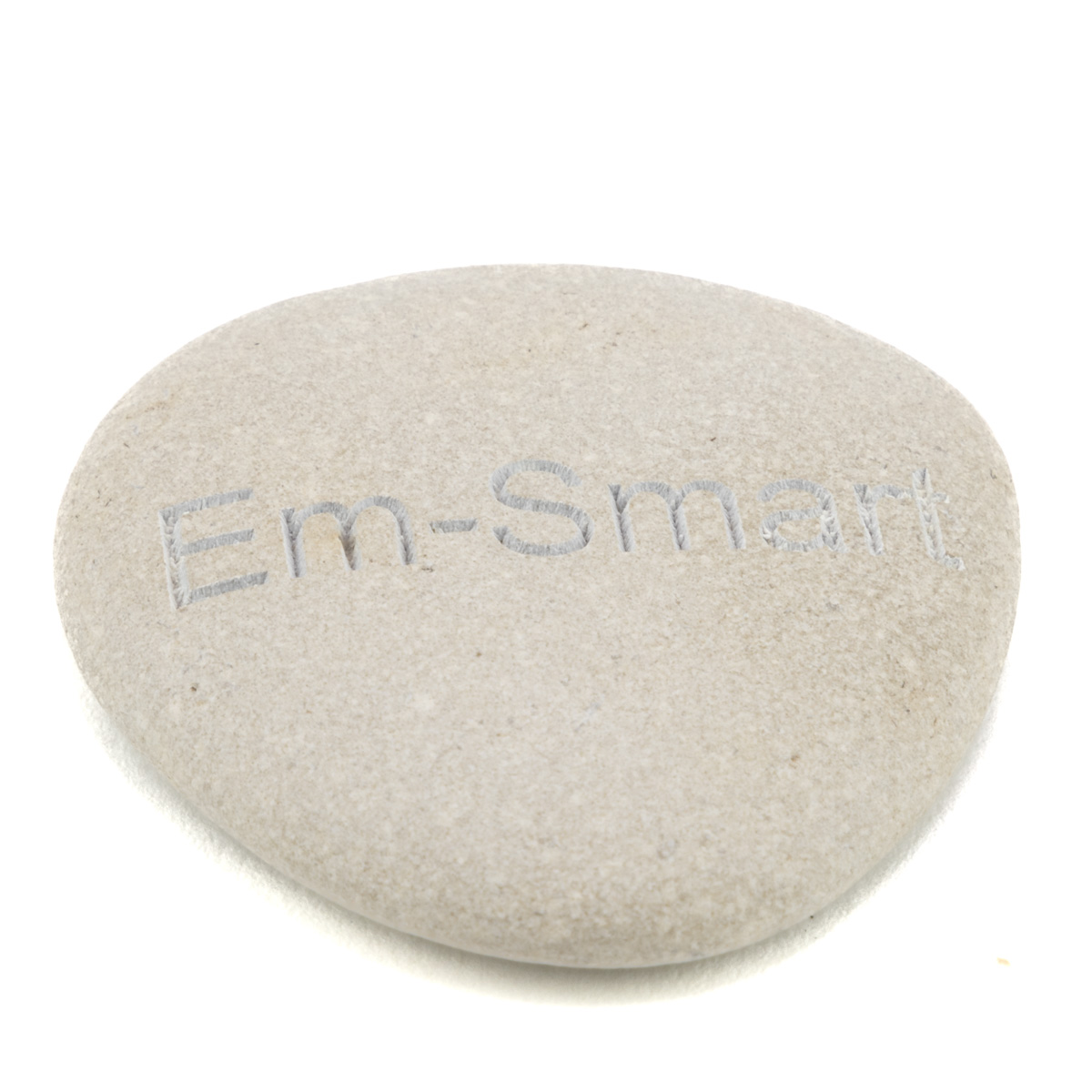

One of many issues I’ve been experimenting with recently is engraving rocks. They’re pretty fast to engrave and the impact is beautiful because of the depth of the engraving. At 100% energy and a velocity of 600 mm/s, 2 passes have been carried out after which I lowered the main target a bit and ran it once more. One of many issues I want the EM-Sensible Twin had was the flexibility to manage the main target by way of the software program to decrease the main target after every move.

Lasers often engrave anodized aluminum very properly, and the EM-Sensible Twin was no exception. I engraved this pet tag at 4000 mm/s at 100% energy and a pair of passes. The engraving solely took 20 seconds. Not solely does anodized aluminum engrave properly, it is usually very simple to acquire deal with, whereas generally different supplies are more durable to see the main target dots on.

One in every of my favourite issues to engrave is the shiny blue anodized metallic tags. The colours you will get from them are improbable. I ran some checks to see what sort of colours I might get. I’m unsure why, however I wasn’t capable of get vary of colours. I nonetheless have to experiment with it.

The EM-Sensible Twin Laser Engraver has the aptitude to make use of a rotary, however one was not included for this evaluate, so I used to be unable to check that performance.

Remaining ideas

The EM-Sensible Twin Laser Engraver seems to be properly constructed and succesful. The dearth of settings for frequent supplies will make it troublesome for inexperienced customers, however nothing {that a} little bit of trial and error received’t care for. The small footprint and enclosure will make it good for many who need a transportable laser for exhibits. The flexibleness of the fiber and diode laser signifies that you’ll have the ability to mark virtually any materials. The Lightburn software program could also be a bit superior for some customers, however there may be additionally EZCAD, which I didn’t take a look at for this evaluate.

What I like about EM-Sensible Twin Laser Engraver

- Detachable base plate

- Enclosed working space

- Nice focusing laser

What must be improved?

- The fan must be simpler to entry for cleansing

- An inventory of settings for frequent supplies could be useful

Worth: $3499.00

The place to purchase: EM-Sensible

Supply: The pattern of this product was offered without cost by EM-Sensible. EM-Sensible didn’t have a last say on the evaluate and didn’t preview the evaluate earlier than it was printed.

Try these different laser engraver critiques!